Features

◇ Large inner support structure can protect the sheet metal from deformation and damage during handling process.

◇ Slot structure efficiently increases the friction force between vacuum pad and workpiece in order to

prevent the oily metal sheets from slipping during the handling process.

◇ 2 hardness of material for option(45 & 60), suitable for sheet metal with different thickness and shapes.

Applications

◇ Car stamped steel plate, oily steel plate

◇ Glass, stamping parts, plywood

◇ Handling normal sheet metal(to avoid deformation)

| How to order | |||||||

| SFF 30 N -G2F ① ② ③ ④ | |||||||

| ① Series | ② Diameter | ③ Material & Hardness | ④ Connection thread | ||||

| SFF | 30 - φ30mm 40 - φ40mm 50 - φ50mm 60 - φ60mm 80 - φ80mm 100 - φ100mm 125 - φ125mm | N - NBR NG - NBR | G2F - Gl/4 Female thread G2M - Gl/4 Male thread G3F - G3/8 Female thread M10M - M10 Male thread M14M - M14X 1.5 Male thread RA - Rectangular adapter | ||||

| Selection | ||||||

| Model/ Connection thread | G2M | G2F | G3F | M10M | M14M | RA |

| SFF30 - 40 | ○ | ● | - | ○ | ○ | ○ |

| SFF50 - 125 | ○ | - | ● | ○ | ○ | ○ |

◇Note: "●"- standard, in stock. "○"-selective,no stock."—"-unavailable.

| Technical parameters | |||||||

| Model | Vertical pull-out force (N) | Lateral pull-out force (N) | Lateral pull-out force N (oily surface) | Inner volume (cm3) | Min. curve radius of workpiece (mm) | Recommended hose dia. (mm) | Weight (g) |

| SFF30 | 45 | 35 | 33 | 2 | 35 | 6 | 11 |

| SFF40 | 72 | 54 | 51 | 4 | 47.5 | 6 | 13 |

| SFF50 | 112 | 90 | 86 | 8 | 70 | 8 | 20 |

| SFF60 | 145 | 102 | 93 | 13 | 81 | 8 | 26 |

| SFF80 | 288 | 212 | 190 | 35 | 11 | 8 | 43 |

| SFF100 | 445 | 322 | 308 | 60 | 141 | 8 | 57 |

| SFF125 | 660 | 475 | 400 | 115 | 165 | 10 | 145 |

◇ Note: Vacuum level is -60kPa, workpiece surface is smooth and clean. The above pull-out force are specified without any safety factor. The value will

changes according to different surface conditions of workpiece

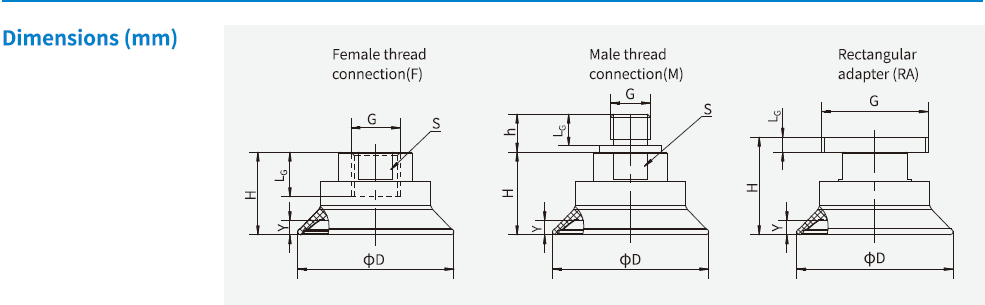

| Model/ Size | D | H | G | LG | h | S | Y |

| SFF30-G2M | 32 | 20 | G1/4 | 12 | 13.5 | 16 | 2.7 |

| SFF30-G2F | 32 | 20 | G1/4 | 11 | - | 16 | 2.7 |

| SFF30-M10M | 32 | 20 | M10 | 12 | 13.5 | 16 | 2.7 |

| SFF30-M14M | 32 | 20 | M14×1.5 | 12 | 13.5 | 16 | 2.7 |

| SFF30-RA | 32 | 24.7 | □32 | 4.7 | - | - | 2.7 |

| SFF40-G2M | 32 | 22 | G1/4 | 12 | 13.5 | 17 | 2.7 |

| SFF40-G2F | 42 | 22 | G1/4 | 11 | - | 17 | 3.7 |

| SFF40-M10M | 42 | 22 | M10 | 12 | 13.5 | 17 | 3.7 |

| SFF40-M14M | 42 | 22 | M14×1.5 | 12 | 13.5 | 17 | 3.7 |

| SFF40-RA | 42 | 26.7 | □32 | 4.7 | - | - | 3.7 |

| SFF50-G2M | 42 | 28 | G1/4 | 12 | 13.5 | 22 | 3.7 |

| SFF50-G3F | 52 | 28 | G3/8 | 13 | - | 22 | 4.7 |

| SFF50-M10M | 52 | 28 | M10 | 12 | 13.5 | 22 | 4.7 |

| SFF50-M14M | 52 | 28 | M14×1.5 | 12 | 13.5 | 22 | 4.7 |

| SFF50-RA | 52 | 32.7 | □32 | 4.7 | - | - | 4.7 |

| SFF60-G2M | 52 | 31 | G1/4 | 12 | 13.5 | 22 | 4.7 |

| SFF60-G3F | 62.5 | 31 | G3/8 | 13 | - | 22 | 6 |

| SFF60-M10M | 62.5 | 31 | M10 | 12 | 13.5 | 22 | 6 |

| SFF60-M14M | 62.5 | 31 | M14×1.5 | 12 | 13.5 | 22 | 6 |

| SFF60-RA | 62.5 | 35.7 | □32 | 13 | - | 22 | 6 |

| SFF80-G2M | 62.5 | 34 | G1/4 | 12 | 13.5 | 22 | 6 |

| SFF80-G3F | 82 | 34 | G3/8 | 13 | - | 22 | 6 |

| SFF80-M10M | 82 | 34 | M10 | 12 | 13.5 | 22 | 6 |

| SFF80-M14M | 82 | 34 | M14×1.5 | 12 | 13.5 | 22 | 6 |

| SFF80-RA | 82 | 38.7 | □32 | 13 | - | 22 | 6 |

| SFF100-G2M | 82 | 36 | G1/4 | 12 | 13.5 | 22 | 6 |

| SFF100-G3F | 103 | 36 | G3/8 | 13 | - | 22 | 9.2 |

| SFF100-M10M | 103 | 36 | M10 | 12 | 13.5 | 22 | 9.2 |

| SFF100-M14M | 103 | 36 | M14×1.5 | 12 | 13.5 | 22 | 9.2 |

| SFF100-RA | 103 | 40.7 | □32 | 4.7 | - | - | 9.2 |

| SFF125-G2M | 103 | 43 | G1/4 | 12 | 13.5 | 22 | 9.2 |

| SFF125-G3F | 128 | 43 | G3/8 | 13 | - | 22 | 12.5 |

| SFF125-M10M | 128 | 43 | M10 | 12 | 13.5 | 22 | 12.5 |

| SFF125-M14M | 128 | 43 | M14×1.5 | 12 | 13.5 | 22 | 12.5 |

| SFF125-RA | 128 | 47.7 | □32 | 4.7 | - | - | 12.5 |